Our Process

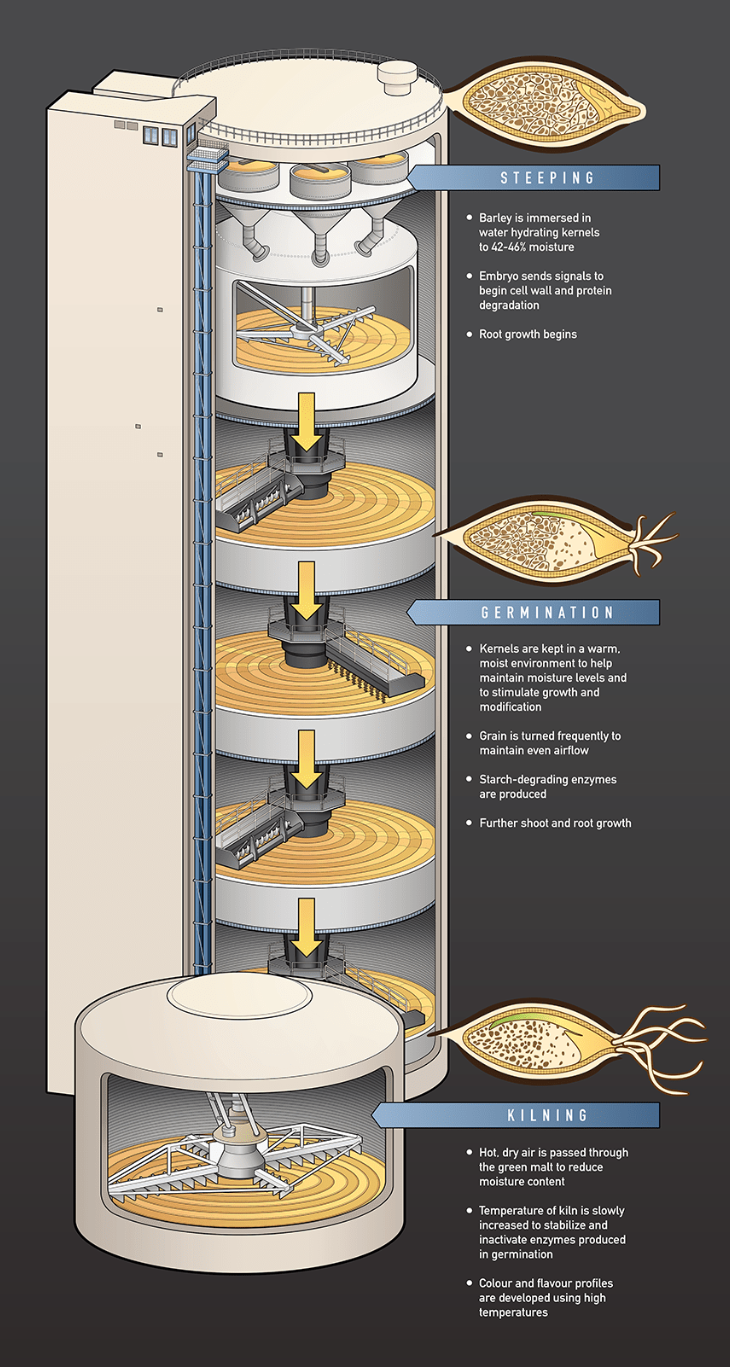

Malting is a biological process that takes place in three steps: steeping, germination and kilning.

Steeping – 36 to 48 Hours

Water is added at suitable temperatures (52-56°F) . Malting quality barley is directed into large steeping tanks filled with water, and air is injected into the water to maintain desired dissolved oxygen levels. A series of immersions will be done to assure that the barley is completely washed and uniformly hydrated. During drain periods, CO2 will be removed from the tanks. The final moisture of the barley will be raised from 12% moisture up to the 44-45% moisture range.

Germination – 96 Hours

After steeping, the grain is gently transported to germination compartments. It will be grown under controlled temperature, water additions, airflow and humidity for approximately four days. The enzymes are activated and the starches are broken down into more simple forms of sugars as dictated by customer requirements.

Drying (Kilning) – 24 to 36 hours

When grown to satisfaction, the fully modified barley is now referred to as “green malt” and is moved into kilns for drying. These are large rectangular or circular vessels with perforated floors. The malt is dried to 4% moisture using high volumes of air at temperatures up to 190° Fahrenheit. The air temperature and airflow are closely controlled to achieve the desired malt attributes.

The principal result of this processing is that the starches have been broken down into more simple sugars, the enzyme potential has been optimized, color generated and the malty flavor developed.

Storage

The finished product is binned in silos to be aged and separated for later blending to customer specifications.